Humans have harnessed the power of wind for thousands of years whether through sails or windmills. The offshore wind industry traces its modern roots to 10 wind turbines just off the Denmark Coast in 1991. In the 30 years since, countries around the world have built tens of thousands of turbines in over 160 offshore wind projects, generating 32,000 MW of power.

While land-based wind turbines are now a common sight across the United States, they have important differences from offshore wind turbines that require a different industry to support development. Modern offshore wind turbines and blades can reach heights over 800 feet and require large components that can only be transported by water. This requires the constant transport of supplies and materials by sea. The actual installation of an offshore wind project is far more complex than a land wind project. Offshore wind projects require specialized equipment, vessels, training and extensive stakeholder engagement and environmental review. Projects can take years, even up to a decade to complete because of the complexity of building an offshore wind project.

Although construction can be challenging, offshore wind projects can produce much more power than their land-based predecessors. Offshore wind turbines capture oceanic wind, which blows more powerfully and consistently than on land, increasing a turbine’s power output and reliability. This effect is further enhanced by a turbine’s blade length, which sweeps over a much larger area and captures more wind. Offshore wind can be an attractive power resource to states and countries that lack available land to develop solar or land-based wind power but have good access to areas offshore from their coasts.

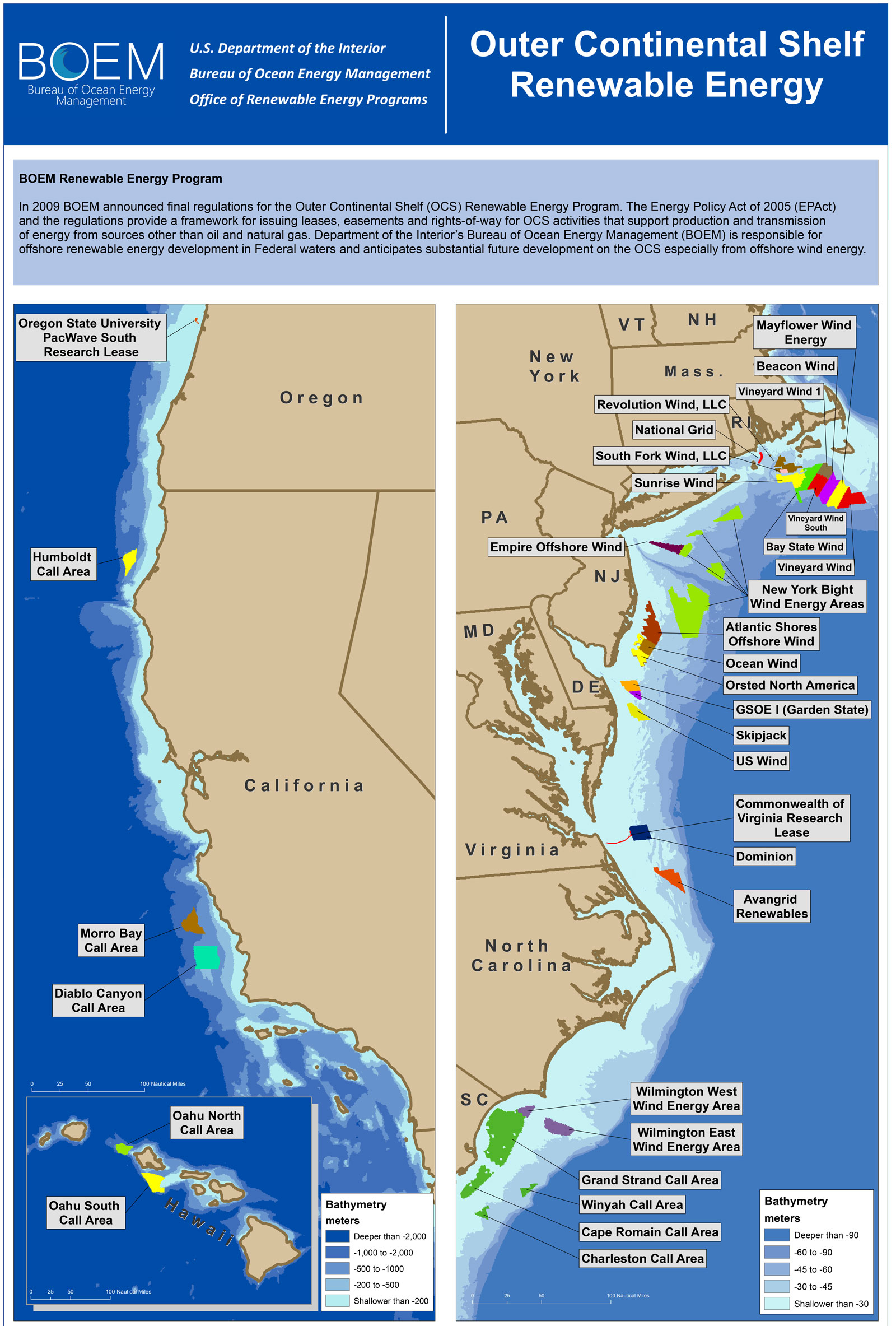

- U.S. Wind Farm Locations

Nearly two dozen projects are moving forward in the United States. Most activity is localized on the East Coast, an ideal location for offshore wind development due to strong winds, shallow waters, and proximity to major population centers. U.S. offshore wind turbines currently use foundations fixed directly to the ocean floor in the shallow waters of the Atlantic Outer Continental Shelf to allow for easier installation. While development has primarily occurred in the Atlantic Ocean, the federal government recently initiated siting processes to expand offshore wind to the Pacific Ocean and the Gulf of Mexico, making offshore wind a national industry.

(Source: BOEM: National Renewable Energy Program)

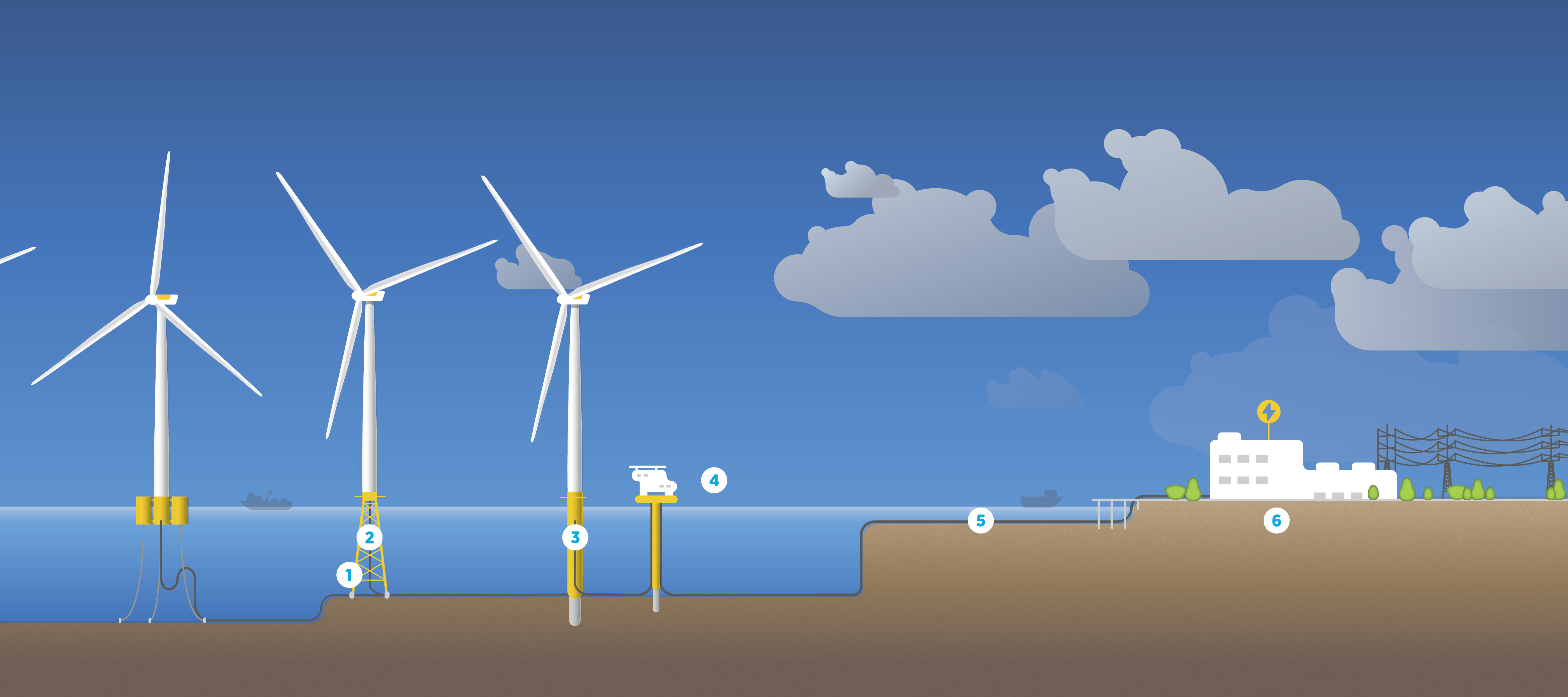

- How Electricity is Generated

Offshore wind harnesses the power of wind to generate clean, renewable electricity. Wind power is generated by converting kinetic wind energy into mechanical energy, and then electric energy. Blowing wind turns turbine blades connected to a rotor, and the rotor then rotates drivetrains or gearboxes to generate electricity. From there, the generated electricity travels by cables to offshore and onshore substations, which connect to the electricity grid where it is delivered to homes and businesses.

Parts of an Offshore Wind Power Generation System

- 1.Wind Tower Generator Foundations & Substructions: These are the structures that support the offshore wind turbines. The support structure can either be fixed to the ocean floor or utilize floating turbine technology that moors the floating foundation in place. The structures are manufactured from steel or concrete.

- 2.Inter-Array Cables: These cables deliver power from each turbine to a centralized offshore substation or multiple substations.

- 3.Wind Turbine Generator: The wind turbine generator consists of a rotor (blades & hub), a nacelle (which houses the components generating electricity), a tower, and a transition piece that connects the tower to the foundation. Towers and transition pieces are made from steel and concrete, and blades are constructed out of composite materials.

- 4.Offshore Substation Platform or Structure: The offshore substation collects the power from the wind project and prepares it to be sent to an onshore substation.

- 5.Export Cable: Power from the wind project is exported from the offshore substation to an onshore substation via one, or more, export cables.

- 6.Onshore Substation: Export cables deliver power to an onshore substation that connects and synchronizes it to the grid.

Want to learn more? Visit the federal government’s Office Energy Efficiency & Renewable Energy.

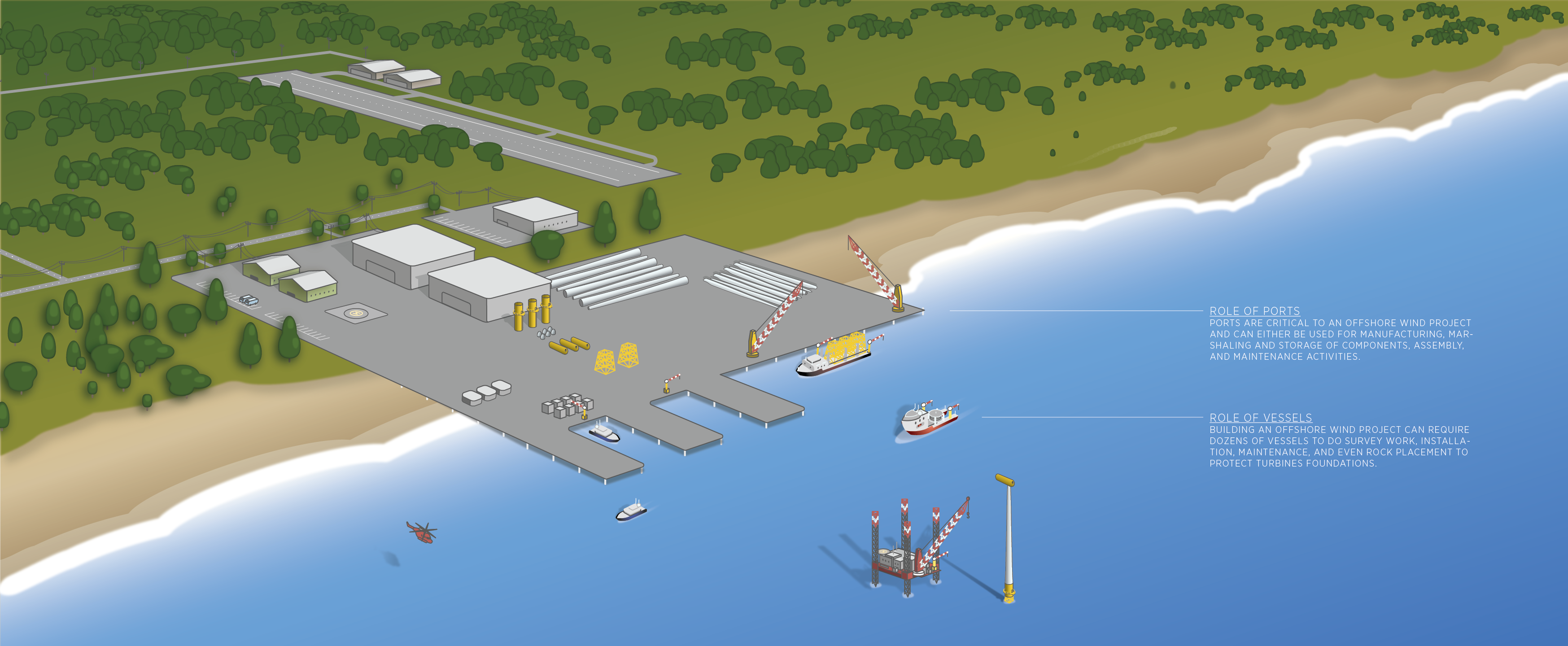

- The Role of Ports & Vessels

Ports and vessels are critical to the construction and operation of an offshore wind project, and Maryland’s rich maritime history means the state is well positioned to leverage its resources to support this new industry. Maryland is strategically located to benefit neighboring states and serve as a supply chain “hub” for specific offshore wind component pieces , Normally, a range of port types are required in service of offshore wind development, including ports for manufacturing, marshalling of materials, assembly, and storage.

Types of Ports

- Manufacturing Ports: These ports host facilities for the production of large offshore wind turbine components, which are difficult to transport over land. Locating manufacturing facilities at ports minimizes transportation needs and facilitates the efficient movement of components to marshaling ports.

- Marshaling Ports: Also known as staging ports, these are used to collect, store, and pre-assemble wind turbine components before they are loaded onto installation vessels. They are strategically located to ensure easy access to the offshore wind farm sites.

- Operating and Maintenance Ports: These ports support the ongoing operation and maintenance of offshore wind farms. They house facilities such as warehouses, offices, and training centers, and serve as bases for vessels that perform regular maintenance activities.

Role of Vessels

Vessels play a critical role in the offshore wind industry, supporting various stages of offshore wind development, construction, operation, and maintenance.

Types of Vessels

- Installation Vessels: These specialized vessels are used to transport and install wind turbine components at the offshore sites. They are equipped to handle the large and heavy components involved in offshore wind projects.

- Wind Turbine Installation Vessels (WTIVs): These are large, self-propelled jack-up vessels equipped with heavy-lift cranes (300-3,000 ton capacity) used for installing offshore wind turbines. They have four support legs that can be raised or lowered and large deck areas for storing and transporting turbine components.

- Wind Farm Construction Vessels (WFCVs): This category includes several specialized vessels: Cable Lay Vessels (CLVs) for laying underwater cables

- Cable Laying Vessels: Specialized vessels designed for laying underwater cables that connect offshore wind turbines to onshore power grids.

- Maintenance Vessels: These vessels are crucial for the regular maintenance and repair of offshore wind turbines. They ensure that the turbines operate efficiently and help minimize downtime.

- Walk-to-Work Vessels (W2W): These service and support vessels are equipped with motion-compensated gangways for accessing wind turbines. They include:Service Operation Vessels (SOVs) Construction Service Operation Vessels (CSOVs) Installation Support Vessels (ISVs) Construction Support Vessels (CSVs)

- Crew Transfer Vessels (CTVs): Small, high-speed craft typically carrying 12 to 24 passengers, used to transport technicians from shore to offshore installations for maintenance and construction work. CTVs are usually catamarans with lengths of 15-30 meters.

- Transport Vessels: Used for transporting large wind turbine components from manufacturing facilities to installation sites.

The offshore wind industry relies on at least 25 vessels per project across all stages, including seafloor survey work, component transfer, cable burial, crew transfer, and turbine installation. The number and types of vessels required can vary depending on factors such as environmental conditions, distance from shore, project size, and specific project requirements.

Maryland’s offshore wind project developers for Momentum Wind and Skipjack have both selected Tradepoint Atlantic, located at Sparrows Point in Baltimore County, MD, to be the center of this maritime activity. That means project components, like towers, foundations, and blades, will either be manufactured in Baltimore or shipped from other locations for final assembly, and then sent out to be installed in the offshore wind projects. Many different types of ships will be moving in and out of Baltimore harbor to complete these tasks and will require services and general maintenance.

- Federal and State Roles

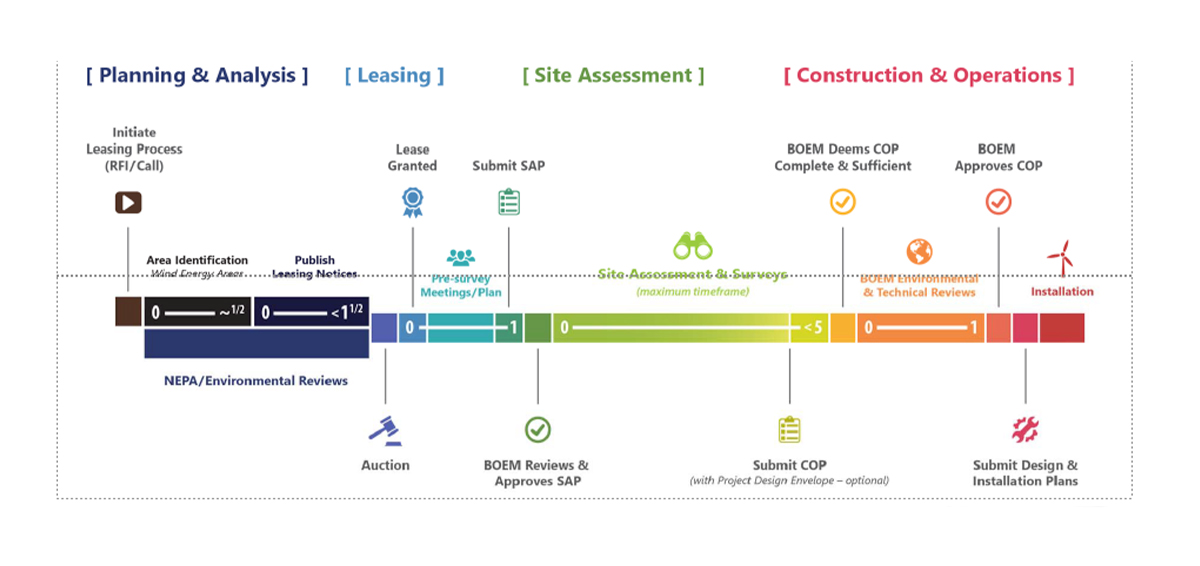

The federal government has jurisdiction over activities on the Atlantic Outer Continental Shelf between 3 – 200 miles out to sea and handles the permitting of nearly all offshore wind lease areas through the Bureau of Ocean Energy Management (BOEM). To ensure that a project is constructed in an environmentally responsible manner and does not significantly disrupt other ocean-users, the federal government extensively studies a project area and construction plan before issuing permits, a process that can take 10 years or more.

(source: BOEM)

Maryland Offshore Wind Lease History

BOEM began the process for identifying suitable sites for offshore wind development in 2010 by bringing together various stakeholders, including local governments and tribes, in what is called an Intergovernmental Task Force. This siting process worked to identify potential lease areas that did not adversely impact environmentally sensitive areas or significantly interfere with other ocean user activities like military operations and shipping. Normally, a wide area, sometimes called a Call Area, is significantly narrowed down over years of stakeholder engagement into Wind Energy Areas (WEAs) and finally lease areas. After identifying suitable areas off the Delmarva Peninsula, BOEM solicited commercial interest from project developers. In 2014, US Wind won a competitive auction for the wind area off the Maryland coast for $8.7 million. The Delaware wind area did not receive sufficient commercial interest to warrant an auction, and in 2012 was granted to Bluewater Wind Delaware; the area was later sold to current leaseholder Ørsted. A more detailed history of each lease can be found on BOEM’s website.

Leasing Process

Offshore wind leasing off the Outer Continental Shelf (OCS) is managed by the Bureau of Ocean Energy Management (BOEM) and involves several key steps to identify, assess, and lease areas for offshore wind development.

Here’s an overview of the process: [developed as a timeline]

Identification and Planning

- Call for Information and Nominations: BOEM begins by issuing a call for information and nominations to gauge industry interest in specific areas of the Outer Continental Shelf (OCS) for potential offshore wind development.

- Area Identification: Based on the responses, BOEM identifies potential lease areas. These areas are then subjected to a high-level assessment to evaluate their suitability for offshore wind projects.

Environmental Assessment

- Draft Environmental Assessment (EA): BOEM prepares a Draft EA to evaluate the potential environmental impacts of leasing and site assessment activities. This document is released for public comment. For the Central Atlantic region, the Draft EA was published on January 12, 2024, opening a 30-day comment period.

- Final Environmental Assessment: After considering public comments, BOEM publishes the Final EA, which includes a detailed analysis of potential impacts and mitigation measures. The Final EA for the Central Atlantic offshore wind lease was published in June 2024, concluding that there would be no significant impacts from lease issuance.

Proposed Sale Notice (PSN)

- Publication of PSN: BOEM publishes a Proposed Sale Notice, detailing the specific lease areas, terms, and conditions. For the Central Atlantic auction, the PSN was published on December 11, 2023, opening a 60-day comment period.

Final Sale Notice (FSN)

- Review of Comments and FSN: BOEM reviews comments received on the PSN and Draft EA, then publishes the Final Sale Notice. The FSN specifies the auction date, final lease areas, auction type and rules, and the deadline for submitting materials for bidding credits. The FSN for the Central Atlantic offshore wind lease was announced on June 28, 2024.

Lease Auction

- Auction: The offshore wind lease auction is held at least 30 days after the publication of the FSN. The auction process involves competitive bidding where qualified bidders vie for lease areas.

Post-Auction Activities

- Lease Issuance: Successful bidders are awarded leases, which grant them the rights to develop offshore wind projects in the specified areas. The lease includes requirements for conducting site assessment and characterization activities, such as geophysical, geological, and archaeological surveys.

- Site Assessment and Characterization: Lessees conduct detailed site assessments and surveys to gather data necessary for project planning and permitting.

- Construction and Operations Plan (COP): Lessees submit a COP to BOEM, detailing the proposed project design, construction, and operation plans. This plan undergoes a rigorous review process, including additional environmental assessments and public consultations.

- Approval and Development: Once the COP is approved, lessees can proceed with the construction and development of the offshore wind project.

Current BOEM Proposed Lease Areas

- Lease Area A-2: Located within 11 nautical miles of three other offshore wind leases and 30 nautical miles from the coasts of Maryland, Delaware, and New Jersey. This area encompasses 101,000 acres suitable for fixed foundations and offers advantages such as proximity to active offshore wind states and reduced costs for export cable installation.

- Lease Area C-1: Situated 37 nautical miles from the coast of Virginia, adjacent to an existing offshore wind lease. This area covers nearly 177,000 acres and is positioned to serve the Virginia market.

The Central Atlantic offshore wind lease process is part of BOEM’s broader strategy to support the clean energy transition and achieve national offshore wind energy goals. This process ensures that potential environmental impacts are carefully assessed and mitigated, while providing opportunities for public input and industry participation.

- BOEM’s Webpage on Maryland State Leasing Information

- BOEM’s Webpage on Delaware State Leasing Information

Learn more about BOEM’s rigorous permitting process here.STATE POWER PROCUREMENT REQUIREMENTS

State governments play a crucial role in offshore wind development by passing laws or enacting policies that require offshore wind power to be part of a state’s sources of energy. Maryland is one of eleven states that currently requires or has set goals to develop offshore wind. States can either enter contracts with a wind developer to purchase power directly or require state utilities to source a percentage of their energy from offshore wind projects. As part of this process, states create standards to ensure projects are cost-effective, provide best value to electricity ratepayers, incentivize local economic development, utilize local ports, and hire local labor.

Maryland’s Offshore Wind Renewable Energy Credit (OREC) Program serves as its main contracting mechanism and has been developed through statue and public service commission orders. Any project receiving an (OREC) must provide a positive net benefit to Maryland’s economy, public health and environment. Maryland’s OREC Program also ensures offshore wind projects conform to labor standards, and include minority, women, and veteran-owned businesses participation in the local supply chain.

Overview of the OREC Program

Legislative Background

- Maryland Offshore Wind Energy Act of 2013: This act established the framework for the OREC program, enabling the development of offshore wind projects.

- Clean Energy Jobs Act of 2019: This act further expanded Maryland’s renewable energy goals, including specific provisions for offshore wind.

- POWER Act of 2023: This act established a new offshore wind goal of 8.5 GW by 2031.

Renewable Portfolio Standard (RPS)

Maryland’s Renewable Portfolio Standard (RPS) mandates that 50% of all electricity sales in the state come from renewable energy sources by 2030. The RPS includes a specific carve-out for offshore wind energy, which is facilitated through the OREC program.

OREC Program Mechanics

Offshore Wind Renewable Energy Credits (ORECs)

- Definition: ORECs are tradable credits that represent the environmental attributes of one megawatt-hour (MWh) of electricity generated by an offshore wind project.

- Purpose: The OREC program incentivizes the development of offshore wind projects by providing a mechanism for project developers to earn revenue from the sale of these credits.

Solicitation Rounds

The Maryland PSC conducts rounds of OREC solicitations to approve offshore wind projects. To date, there have been two rounds:

- Round 1 (PSC Case No. 9431):Application Received

- Round 2 (PSC Case No. 9666):Application Received

Approved Capacity

- Total Approved Capacity: The Maryland PSC has approved a total of 2,022.5 MW of offshore wind capacity through the two rounds of OREC solicitations. This capacity is expected to power approximately 600,000 homes and create significant economic benefits for the state.

- In January 2024, offshore wind developer Orsted pulled their OREC contract with the Maryland PSC, reducing Maryland’s offshore wind capacity from the approved 2,022.5 to just over 1,100 MW and the ability to power 300,000 homes.

Economic and Environmental Impact

Job Creation and Economic Development

- Job Creation: The approved offshore wind projects are estimated to create over 12,000 full-time employment (FTE) jobs during development and construction, and over 3,000 FTE jobs during the operation and maintenance phases.

- US Wind’s project alone accounts for over 10,000 FTE jobs during project development, construction, operations and maintenance.

- Capital Investment: The projects have a capital investment requirements of 30% of total expenditures in state, including investments in the following: $76 million for a steel manufacturing facility, $40 million for port infrastructure upgrades, and a 150 million monopile foundation manufacturing facility.

Environmental Benefits

- Emission Reductions:

- The carbon emissions associated with the lifecycle of offshore wind turbines, including manufacturing, construction, operation, and decommissioning, are relatively low. The emissions saved throughout a wind turbine’s lifespan are up to 50 times greater than the emissions from its entire lifecycle

- According to the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL), achieving the national target of 30 GW of offshore wind by 2030 will help the United States avoid up to 78 million metric tons of CO2 annually. This translates to approximately 2.6 million metric tons of CO2 avoided per GW of offshore wind energy each year

- Offshore wind energy helps reduce greenhouse gas emissions by displacing electricity generated from fossil fuels. This reduction in emissions mitigates climate risks, such as extreme weather events, and improves air quality by reducing pollutants associated with fossil fuel combustion

- Health Improvements

-

-

- By reducing air pollution, offshore wind energy contributes to better public health outcomes, lowering the incidence of respiratory diseases and other health issues related to poor air quality

-

Comparison with Traditional Fuel Sources

Fossil Fuel Emissions

- Coal: Burning coal for electricity generation emits approximately 2.2 pounds of CO2 per kilowatt-hour (kWh). For a GW of coal-fired power operating at full capacity for a year, this would result in about 9.7 million metric tons of CO2 emissions annually.

- Natural Gas: Natural gas plants emit about 1.0 pound of CO2 per kWh. A GW of natural gas power would emit approximately 4.4 million metric tons of CO2 annually.

Offshore Wind vs. Fossil Fuels

- Emissions Savings: Replacing a GW of coal-fired power with offshore wind would save approximately 9.7 million metric tons of CO2 annually. Replacing a GW of natural gas power would save about 4.4 million metric tons of CO2 annually.

More details about how Maryland procures offshore wind power in the history section.